Assemble a DIY 3D printer Kit

When jumping into the world of 3D printing, I believe it’s a good idea to assemble a kit yourself to get a basic idea of how they are built and how 3D printers work. While following the instructions and putting the parts together you’ll gradually learn all the terms and vocabulary associated with 3D printing which will make it easier to solve problems in a later stage.

Basic skills you need to get started

That said, nowadays, assembling a kit comes down to connecting a few parts with screws and cables. Most of the time, all the hard work is done in the factory. So no soldering or drilling is required. The assembly time of cheap 3D printer kits ranges between 1 and 16 hours, depending of the level of knowledge of the user.

Basic Skills Required:

- A little better than basic understanding of electronics

- A little better than basic understanding of mechanical components

- A little better than basic computer skills

Why DIY kits still exist mainly has to do with saving costs, because the components can be packed and shipped more efficiently. There are a lot of under $750 cheap 3D printer kits out there but we will focus on the best.

Best Cheap 3D Printer Kits

- Original Prusa i3 MK2 DIY Kit

- Tevo Black Widow

- Micromake 3D Gecko CoreXY

- Velleman K8200 Vertex

- ZONESTAR Prusa i3

- Anet A8

- Makers Tool Works MiniMax

- Makerfarm Pegasus 12″

- Makerfarm Pegasus 8″

- JGAURORA A-3 Prusa i3

- Anycubic Delta

- CoLiDo

- Anycubic Prusa i3

- FUNFLAG Prusa i3

- Sintron Prusa i3

Original Prusa i3 MK2 DIY Kit

Open source runs through the veins of Prusa Research. Founder Josef Průša is a long time contributor to the RepRap community. His latest model, the MK2 was released in May 2016.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Original Prusa i3 MK2 kit | Czech Republic | FFF / FDM |

| DIY Kit | Out of stock |

Tevo Black Widow DIY Kit

Tevo is a Chinese manufacturer of cheap open source DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| TEVO Black Widow | USA | FFF / FDM |

| DIY Kit | $544.49 |

Micromake 3D Gecko CoreXY

Micromake is a 3D printer manufacturer from China.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Micromake 3D Gecko CoreXY | USA | FFF / FDM |

| DIY Kit | $741.00 |

Velleman K8200 Vertex DIY Kit

Velleman is a Belgian manufacturer of high quality open source DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Velleman K8200 Vertex | USA | FFF / FDM |

| DIY Kit | $650.00 |

ZONESTAR Prusa i3 DIY Kit

Based in China, ZONESTAR is known for it’s cheap 3D printer kits with sturdy metal frames.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| ZONESTAR Prusa i3 | USA | FFF / FDM |

| DIY Kit |

Anet A8 DIY Kit

Anet is a Chinese manufacturer of cheap 3D printer kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Anet A8 | USA | FFF / FDM |

| DIY Kit |

Maker’s Tool Works MiniMax DIY Kit

Maker’s Tool Works is one of the first manufacturers of DIY 3D printer Kits. Starting with the release of the original MendelMax in 2011

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Maker’s Tool Works MiniMax | USA | FFF / FDM |

| DIY Kit | $699.00 |

Makerfarm Pegasus 12 DIY Kit

Makerfarm is an American manufacturer of affordable, high quality DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Makerfarm Pegasus 12″ | USA | FFF / FDM |

| DIY Kit | $710.00 |

Makerfarm Pegasus 8 DIY Kit

Makerfarm is an American manufacturer of affordable, high quality DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Makerfarm Pegasus 8″ | USA | FFF / FDM |

| DIY Kit | $410.00 |

JGAURORA A-3 Prusa i3 DIY Kit

JGAURORA is a Chinese manufacturer of cheap 3D printer kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| JGAURORA A-3 Prusa i3 | USA | FFF / FDM |

| DIY Kit | $299.00 |

Anycubic Delta DIY Kit

Based in China is Anycubic, a 3D printer manufacturer known for their high quality DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Anycubic Delta | USA | FFF / FDM |

| DIY Kit | $299.99 |

CoLiDo DIY Kit

CoLiDo is a brand of a manufacturer called Print-Rite.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| CoLiDo DIY | USA | FFF / FDM |

| DIY Kit | $230.00 |

Anycubic Prusa i3 DIY Kit

Based in China is Anycubic, a 3D printer manufacturer known for their high quality DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Anycubic Prusa i3 | USA | FFF / FDM |

| DIY Kit |

FUNFLAG Prusa i3 DIY Kit

FUNFLAG is a Chinese manufacturer of affordable DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| FUNFLAG Prusa i3 | USA | FFF / FDM |

| DIY Kit |

Sintron Prusa i3 DIY Kit

Sintron is a Chinese manufacturer of cheap DIY kits.

| 3D printer | Ships from | Type | Print area | Assembly | Price | |

|---|---|---|---|---|---|---|

| Sintron Prusa i3 | USA | FFF / FDM |

| DIY Kit | $219.95 |

Bed moving over z-axis or y-axis?

Cartesian, Delta, Scara and Polar are all different types of 3D printers. What is interesting, is that within the Cartesian 3D printers there are two segments: let’s say the Prusa Mendels and the Ultimakers. A Prusa moves the bed over the y-axis and an Ultimaker moves the bed over the z-axis. Both have their pro’s & con’s but it generally comes down to this:

A 3D printer with a bed that moves over the z-axis can achieve higher speeds. A bed which moves over the y-axis can handle more weight, is mechanically simpler and is easier to maintain. Therefore I recommend to opt for a Prusa type in the case of purchasing a kit.

Materials used for the frame

It may appear that these kits all consist of the same materials, but please keep in mind that when assembled, look at things like the rigidity and weight of the 3D printer kit itself.

3D printers have quite a few moving parts and can shake quite a bit, especially at higher speed prints. Therefore you need a little weight to keep your machine into place and not find it vibrating itself off the table and onto the floor.

3D printers have quite a few moving parts and can shake quite a bit, especially at higher speed prints. Therefore you need a little weight to keep your machine into place and not find it vibrating itself off the table and onto the floor.

You must also be cognisant of a flimsy frame as this could lead to distorted and skewed prints. For this reason I prefer solid heavy frames made of wood, metal or melamine. With that in mind some cheap 3D printer kits will use a metal frame but is so thin that it really provide nothing in terms of rigidity. A good metal frame that is considered tough will range from 3.0mm to 6.5mm in thickness.

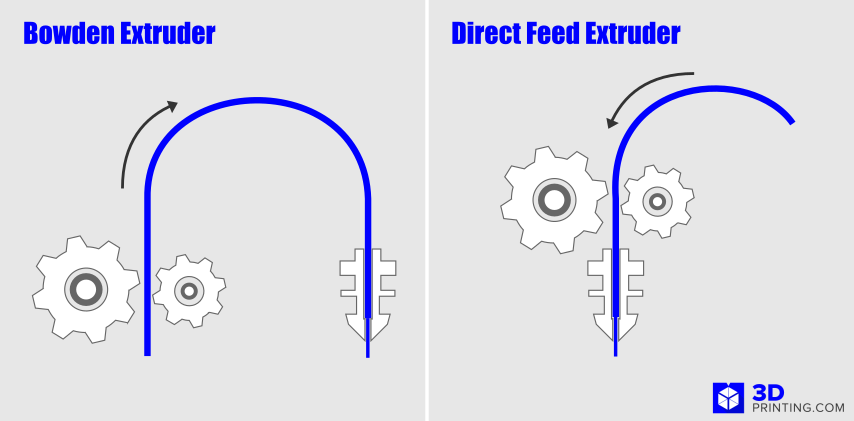

Bowden versus Direct Feeder system

You might want to take in consideration what type of extruder feed system you’ed like to work with. A bowden type or a direct extruder feed. The Prusa’s of this world most of the time have a direct extruder and the Ultimaker’s a bowden. Direct extruders are placed on the moving parts of the 3D printer. The heavy stepper motor of the direct extruder slows down the printing speed and can take down the print quality. Bowden printers can achieve higher print speeds. Direct feed extruders are better with specialty flex like materials.

Advantages of Bowden Extruder

- Lesser weight of moving parts, higher accuracy prints at high speed

- Less momentum to overcome, therefore faster printing times

Disadvantages of Bowden Extruder

- Finer tuning of extruder to compensate tube length play

- Challenge to print flexy filaments, extruder has problems gripping the flexible material

- You can’t finish your filament spool, you always have leftovers

Advantages of Direct Feed Feeder Systems

- More accurate direct feed of filament to hotbed, easier retraction less ooze

- Handles flexi like filaments better

- You can finish your filament spool till the end

Disadvantages of Direct Feeder Systems

- Additional weight of motor on carriage causes issues with quick changes in direction

Filament Guide – Tips & Tricks

As this is your first 3D printer and initial cost is a factor (in this case under $750), we also need to consider the running cost of the machine itself! Filament spools are probably the most expensive running costs of any 3D printer, so it is always a good idea to take a look at a filament guide to ensure choosing a good filament for decent quality prints.

Most intermediate / professional users will advice not to go cheap and they’d be completely correct. However, this is your first ever 3D machine, which will result in weeks / months of trial and error and therefore it makes no sense to fork out money on expensive filaments that will probably go to waste anyway… So here are a few tips and tricks to ensure decent printing quality using lesser expensive filaments, while protecting your new printer from reoccuring damage:

Moisture free filaments

Certain filament materials such as PLA easily absorb moisture from the atmosphere. It is this absorption that can cause problems such as effecting print quality and cause damage your hot-end through blockage.

- Hot-End Damage: Moisture absorption causes filament swell. If the swelling is sufficient enough, the plastic will simply block up the nozzle and may cause permanent hot-end damage.

- Print Quality: During melting of the plastic, the trapped moisture turns into steam and causes some bubbling. It is this bubbling that interferes with the extrusion rate and results in a model that lacks strength and quality… not to mentioning not looking good!

- Solution: To combat filament moisture absorption and serious damage to your new equipment, one inexpensive solution is to buy vacuum bags. Place your filament spool in the bag, throw a couple of silica gel packs and suck all the air out.

Dust free filaments

Dust is an other problematic factor. This is because the dust will find its way onto the filament even during the printing process. As the filament is fed through, so is the dust which eventually reaches the nozzle and can either cause a partial blockage which in turn compromises your print quality or a complete blockage

- Solution: A simple and inexpensive unviversal filament filter can be installed that will automatically remove any dust particles while the filament is being fed through.

Assembly Printer Guide

As I mentioned earlier you will encounter problems. As a rule, the better the initial built the lesser the problems you may encounter or need to solve later on. A good initial built starts with great assembly guides and quality parts. I prefer watching assembly video guides first, because I’m more a visual learner and get a better understanding by seeing how someone else does it.

Unfortunately some of the great guides out there have their flaws and to add to that the 3D printing world is changing so quickly. It could end up your kit has some new parts in it replacing old ones that are not mentioned in the guide or look just a bit different. As a result this could lead to some confusions so prepare to get stuck at a certain points and re-assess. Some of these companies seem to assume the users are as tech or engineering savvy as their peer group which may not always be the case.

Sometimes the best guides are made by fans. A great example is this MakerGear M2: The Ultimate Tips & Tricks Guide.

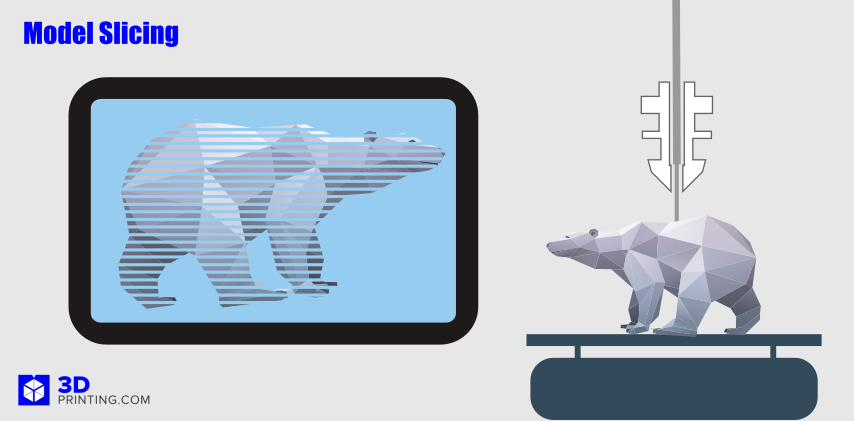

Slicing model software

Typically your 3D generated model will come in .STL format, usually created using a 3D package such as Blender. This is the file that your printer must read in order to print out the model. However, most 3D printers create solid parts through the process of building up layers of the plastic being used. Therefore, a slicer software is required to slice up the solid model into layers which is a language the 3D printer understands in order to start and complete the print.

There are several slicers out on the market, some of which are fantastic and pretty much plug and play, but they can cost a pretty penny. So it is very much a question of balancing the price of the slicer to the price of the printer itself. Luckily there are several great Open Source slicers out there that are effectively free for download and use. We recommend you download and try some of them out for yourself as it is very much a question of personal taste… not to mention that some slicers can even have an affect on the final print quality.

Support

So this brings me to my next point, support. Support comes in many shapes and forms. Does the company deliver one-on-one customer support with a helpdesk employee via mail or phone? Do they have a forum, a Google or Facebook group where the community helps out each other? All of these can be very helpful tools in the event you get stuck on something whether it be the 3D printer or the print outcome itself. In addition this can also be a great way to get involved in the community itself and some day you may be helping someone else with a problem you overcame.

All in all I recommend first consulting customer reviews. Hands on usage from the public and real users is the best way to cut through all the marketing hype and it is the best way to gauge the quality and function of a product before committing your money.